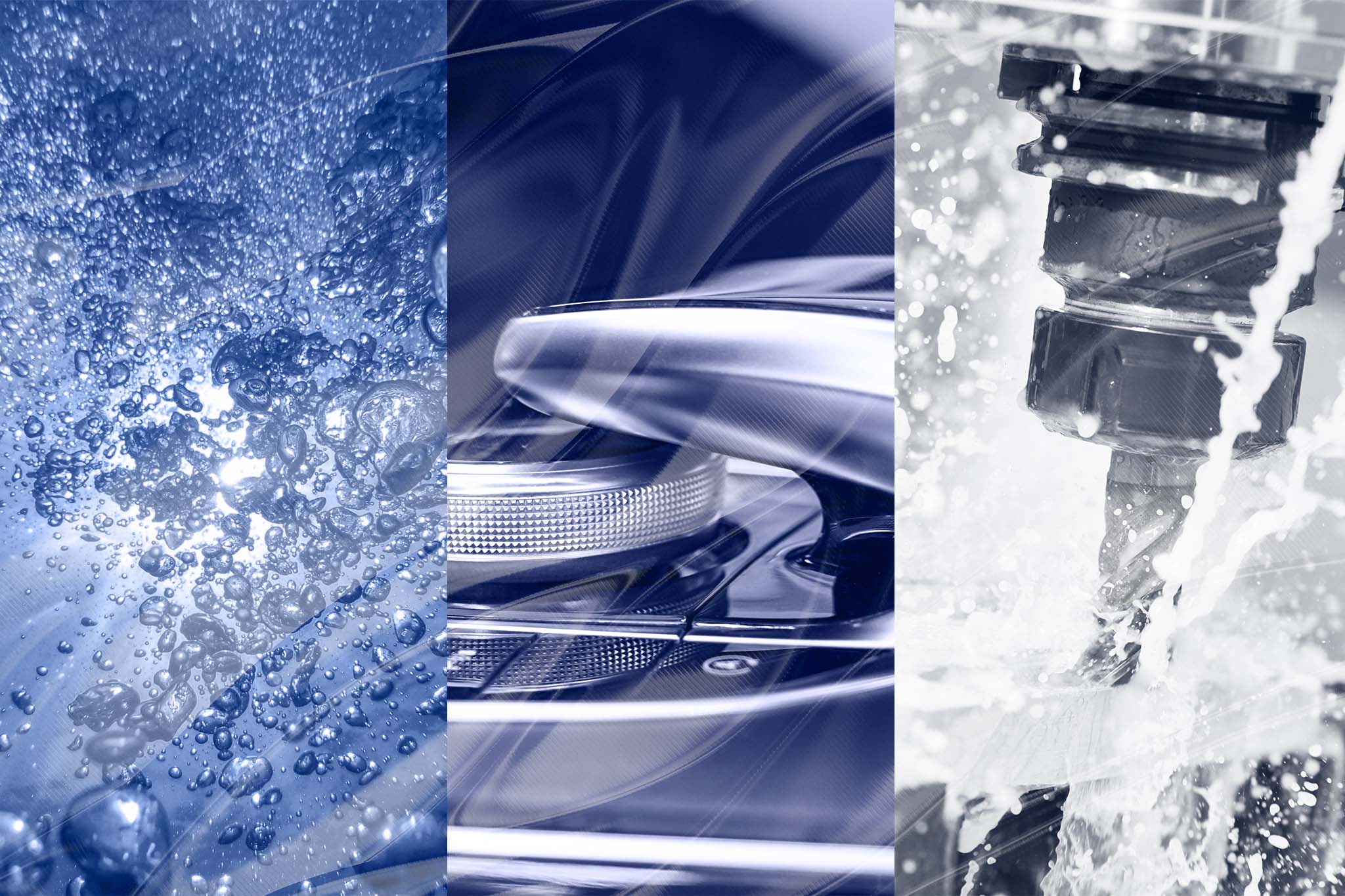

CENTRIPURE™

Filtration station with clean tank

-

SPECIALMachining & metalworking

The special feature of the CENTRIPURE™ is to filter the fluid directly into an independent clean tank, so the fluid returned to the process is guaranteed 100% filtered. The CENTRIPURE™ is available in a standard version with 2 filter housings and a 250-liter tank or in a customized version with unlimited capacity tank, belt filter, filter housings, high pressure pumps, sludge and chips evacuation tank, cooling unit...

Custom filtration

- FILTECH™ : Pleated filter cartridge (filtration 1 to 100 µm – washable and reusable – set up without tools)

- BAGTECH™ : Pre-filtration filter bag (filtration 150 to 600 µm – washable and reusable – set up without tools)

- MAGTECH™ : Magnetic filtration (5 kg of captured particles – easy installation and cleaning – power from 3000 to 11000 Gauss)

- OILTECH™ : De-oiling microfibers (high retention capacity – hydrophobic fibers – 500 g captures 6 l of oil)

- WATERTECH™ : Water absorbent (removes water present in whole oils)

High pressure cutting fluid version

- Increased capacity: on-board lubricant tank from 250 to 2000 liters depending on requirements

- Temperature control: the COOLTECH™ option guarantees constant cutting parameters by maintaining the fluid at an optimal temperature (cooling or heating)

- Integration of HP machine pumps : In order to reduce your costs, we propose to deport the HP machine pumps directly on the CENTRIPURE™.

Design to specification

Because our customers have different needs from one another, we design CENTRIPURE™ to order. Whether it is related to size, capacity or shape constraints, we adapt to your requirements.

Specifications

- version

-

SPECIALMachining & metalworking

- Materials

- Polypropylene