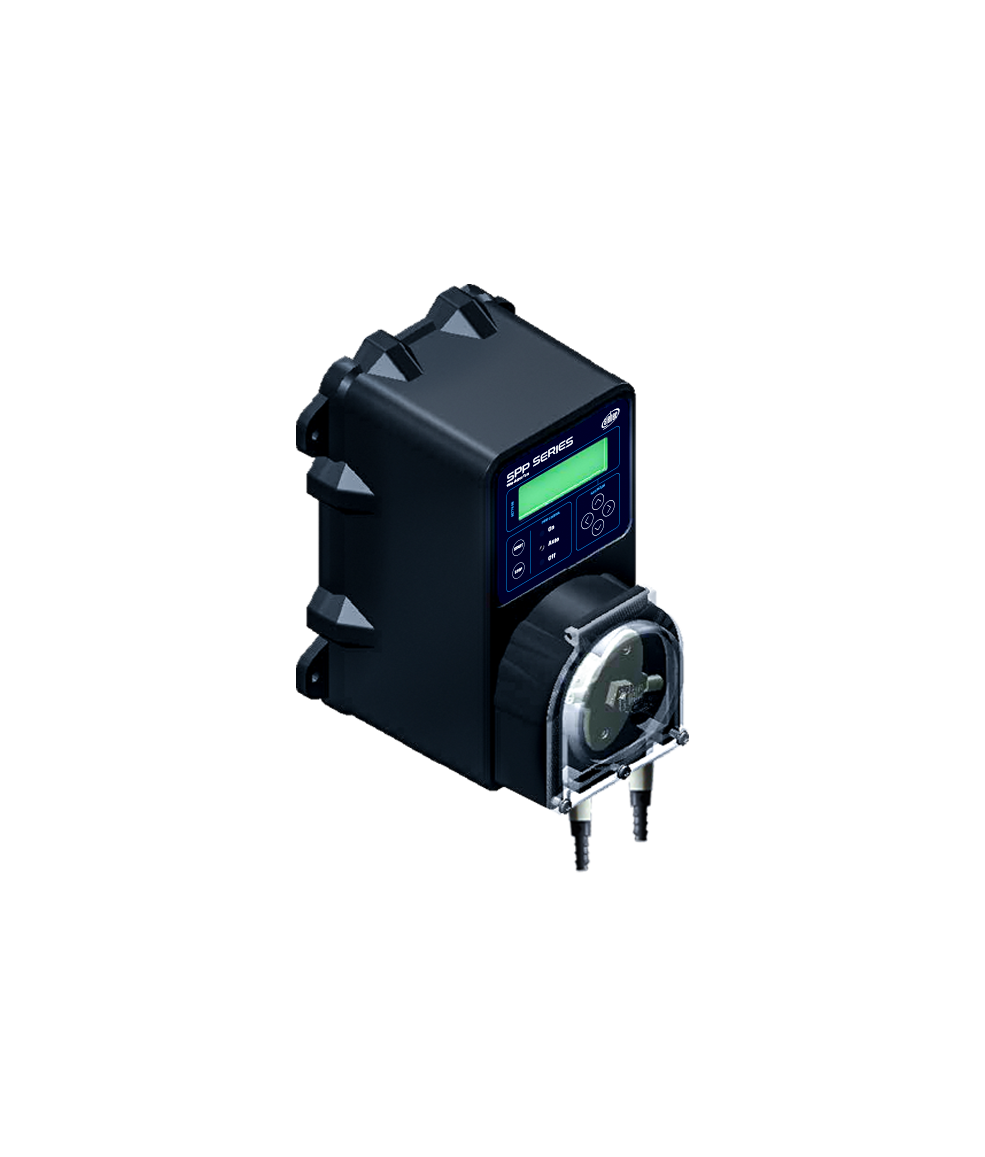

SPP STEP

Programmable dosing pump

- 28 l/h

- 65 RPM

- 20 W

Compact and easy to integrate, this peristaltic dosing pump is ideal for intermittent volumetric dosing. It ensures precision and reliability, with an intuitive interface and an ergonomic design that makes it easy to use and replace the tubing. Its features include pH/redox regulation, timer programming, and end-of-product detection, along with a wide range of additional options.

Revolutionize Your Dosing Process.

Ease of Integration

Its ultra-compact design facilitates integration into tight spaces. Plug it directly into a 230V 50Hz outlet for quick installation without additional equipment.

Material Options

Tubes available in Teknoprene®, Silicone, and Viton®.

Connectors available in PP, PVDF, or Nylon.

Intuitive Interface and Ergonomics

Its interface is designed for optimal use with a clear screen and intuitive buttons. The pump features a pivoting cover and practical clearances that simplify tube replacement. These features allow for smooth handling and quick maintenance, reducing downtime and increasing operational efficiency.

Focus on Modularity.

Design your ideal solution with a programmable interface and a wide range of inputs/outputs, allowing complete adaptation to all your specific needs. Conditions are fully customizable through the interface.

A Wide Range of Features

Volumetric Dosing

The SPP™ STEP pump is designed to deliver precise volumes of liquid with each cycle and maintain a constant flow rate, ensuring the reliability required in industrial processes where dosing precision is critical. The recalibration function adjusts dosing according to specific process needs and variations in operating conditions (density, viscosity, temperature), ensuring optimal flexibility.

Ultra-Precise Volumetric Dosing with Integrated Volumetric Flowmeter (Option)

This option adjusts dosing based on external variables such as pressure or temperature, providing maximum flexibility to meet the dynamic demands of complex industrial environments.

Timer Programming

The SPP™ STEP pump includes a weekly programming feature that allows you to inject a set volume at specific days and times.

Proportional Injection with Integrated Flowmeter or Volumetric Counter on Production Line

This solution allows the SPP™ STEP pump to connect to a flowmeter/volumetric counter on the production or supply line. The SPP™ STEP pump will automatically and proportionally inject the product into the supply line. Application example: injection of cutting fluid concentrate (5%) into the machine filling line.

pH or Redox Regulation

Thanks to its 4-20mA analog input, a pH or redox probe can be connected to the SPP™ STEP pump. Through the programmable interface, you can set the control parameters and settings.

PLC Control

The SPP™ STEP pump can be controlled by external PLCs through its various inputs. Impulse signal to order the pump to inject a defined amount of liquid or continuous signal for pump start-up…

End of Product Detection

The suction lance with an integrated sensor can be connected to the SPP™ STEP to alert the user when the dosing container/drum is empty. An empty container message appears on the screen. Fault reporting is possible via the on/off output or on a signal tower.

Error Reporting

The SPP™ STEP pump includes 3 on/off outputs that allow information to be relayed to a PLC or signal tower.

Caractéristiques

- Flow rate (l/h)

- 28

- Max pressure (bar)

- 2

- Power (W)

- 20

- Power supply

- 230V single phase

- Rotating speed (RPM)

- 65

- Frequency (Hz)

- 50

- Drive

- Peristaltic

- Materials

- Polypropylene, PVDF, Nylon, Tecknoprene®, Silicone, Viton®

- Width (mm)

- 172

- Depth (mm)

- 190

- Height (mm)

- 264

- Weight (kg)

- 1,5