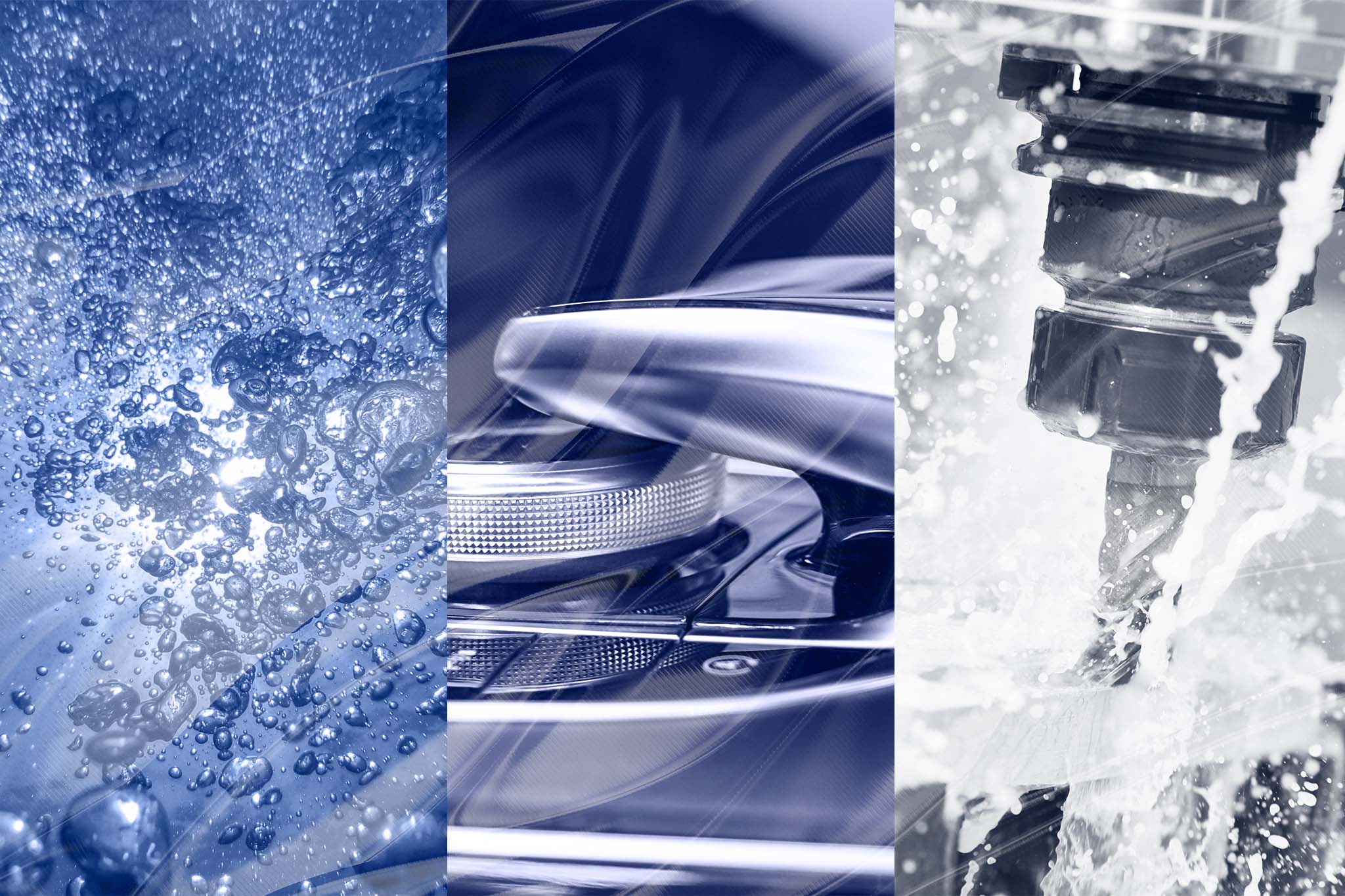

EASYMIX

Monitoring & correction of cutting fluids

Intelligent, this station provides remote quality monitoring of cutting fluids and automatic correction of soluble concentration. The EASYMIX™ is the only one to provide an accurate reading of lubricant properties -at all times-, it automatically corrects the soluble concentration, it manages the lubricant level in the machine tank and notifies the user via a cloud application.

Features & benefits

The assurance of a quality machining

Optimal soluble concentration. Perfect lubrication of cutting tools.

Maximum autonomy

Automatic monitoring and correction (soluble concentration, pH, temperature) without intervention. Management of the lubricant tank level.

Personal space in the cloud

No on-site visits required. 24/7 autonomy. Data history.

Features

- Time programmer (start and stop of operation or synchronization with the start of the plant).

- Alarm settings (concentration, pH, temperature, filter clogging, level detection, …).

Exclusive to SIEBEC

The EASYMIX™ station is the only one on the market with the following features:

- Accurate reading of lubricant properties, even over time

- Automatic correction of the soluble concentration

- Management of the lubricant level in the machine tank

- Notification & monitoring via cloud application

Cloud option

- Transfer of PLC data to a secure cloud server.

- Real-time visualization of parameters on computer or smartphone.

- Storage of the history.

- Sending email in case of anomaly.

Specifications

- Applications

- Recyclage des fluides de coupe, Filtration des fluides de coupe