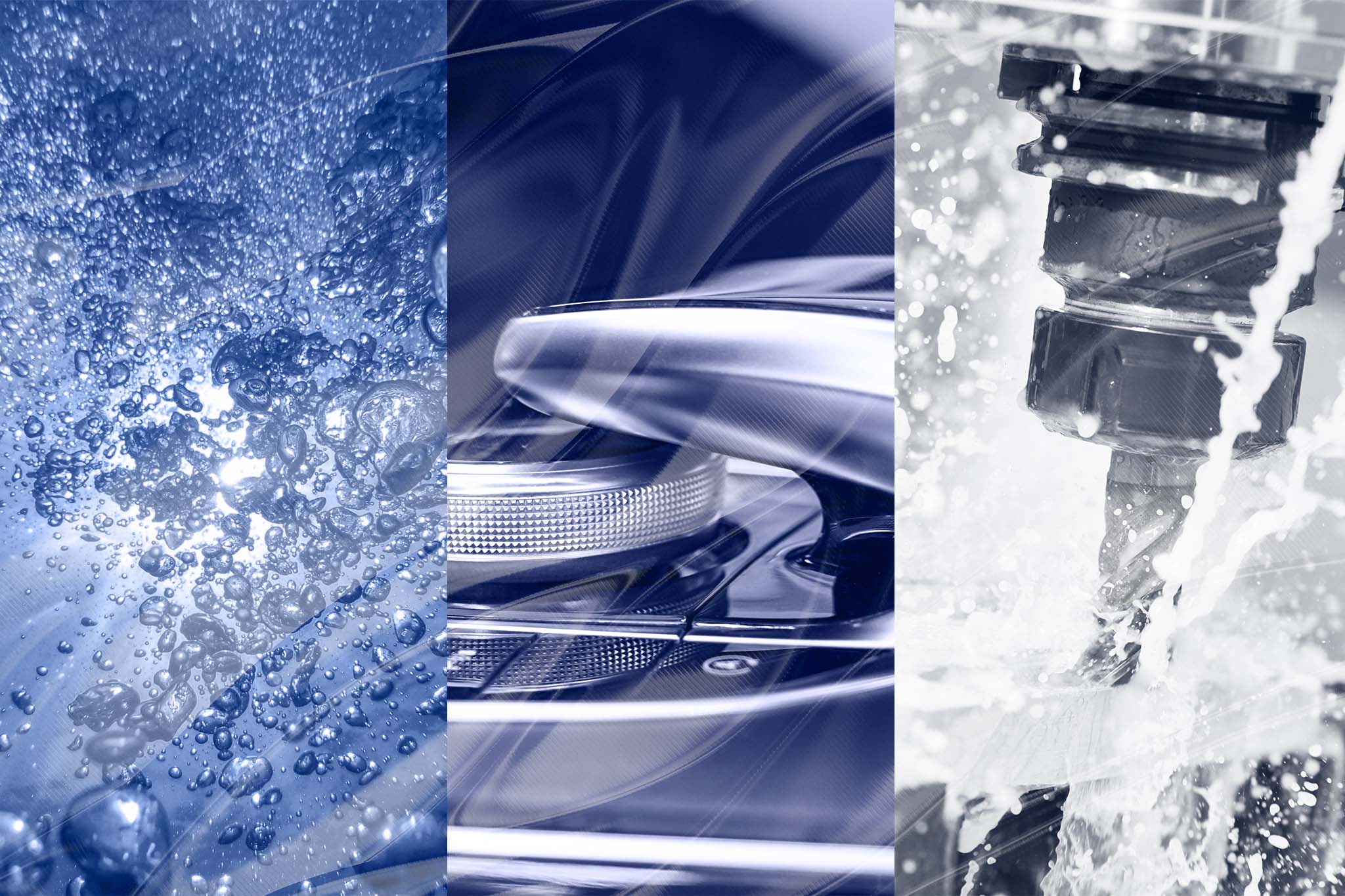

MINIPURE™

Filtration & de-oiling of cutting fluids

-

SPECIALMachining & metalworking

This compact station offers continuous filtration of cutting fluids to maintain excellent machining conditions.

Features & benefits

Protection of the machine tool

No risk of clogging of the original filter, protection of the spindle rotating joints.

Excellent cutting parameters

Purified, particle-free oil and supernatant oil for optimal lubrication and cooling.

Improved service life

Maintain fluid characteristics and increase cutting tool life.

Complete filtration

Eliminates microscopic particles, fine particles, solid particles and supernatant or emulsified whole oils from machine lubrication (case of soluble oils).

Custom filtration

- FILTECH™ : Pleated cartridge (filtration 1 to 100 µm – washable and reusable – set up without tools)

- BAGTECH™ : Pre-filtration bag (filtration 150 to 600 µm – washable and reusable – set up without tools)

- MAGTECH™ : Magnetic filtration (5 kg of captured particles – easy installation and cleaning – power from 3000 to 11000 Gauss)

- OILTECH™ : De-oiling microfibers (high retention capacity – hydrophobic fibers – 500 g captures 6 l of oil)

- WATERTECH™ : Water absorbent (removes water present in whole oils)

Options

- SAFETECH™ : protection against dry running

- Mobile cart or fixed skid

- Cased station

- Sprinkler kit for machine cleaning

- Fixed or floating surface skimmer

Specifications

- version

-

SPECIALMachining & metalworking

- Flow rate (m³/h)

- 9

- Power supply

- 230V single phase

- Materials

- Polypropylene

- Width (mm)

- 1100

- Length (mm)

- 663

- Height (mm)

- 1242

- Applications

- Filtration of cutting fluids

- Filtration media

- L-TECH™ (pleated cartridge), CARBONCANTECH™ (activated carbon), BAGTECH™ (Filter bag)